About the Product - MIDAS: Idea & Development

As a permanent makeup artist, you know how MIDAS needles work and which ones you need for different services. Ever been curious how this microblading system came to be? Eric Chou, CEO and Director of Product at MEI-CHA, shares how MIDAS was developed.

\\

How did it start?

As we look back on the history of the brand, MEI-CHA has grown to where we are now because of our continuous effort to provide quality and reliable products. We are always looking at our product lines and doing what we can to improve them. Manual permanent makeup has existed long before the term “microblading” was introduced, but the products on the market leave room for improvement. When we noticed the trend of microblading gaining popularity in the North American market, we knew the tool could be perfected and started toying around with the idea of our own version of a modern-age microblading tool.

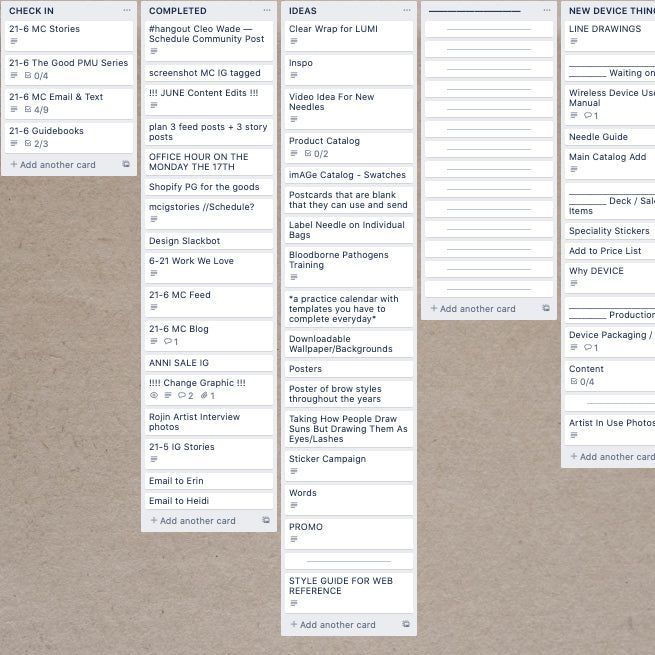

What was the ideation process like?

Research. Lots and lots of market research. We focused on identifying market needs and concept development at this stage. We sourced all kinds of Microblading stylus and needles from the market to compare, measure, and test. We gathered feedback from artists because we believe the customers’ needs and user experience are the most important aspects of product development. Talking and listening to our users are definitely the biggest determining factor to the success of Midas. There were three main problems with the tools artists were using:

- Users, especially beginner artists, had a hard time setting up the angle needles and often had to readjust during the procedure.

- Users had to manually insert the needles into the handle, which is neither safe nor hygienic.

- Pigment buildup, especially in the section between needle and stylus.

The research gave us a good direction of what we wanted to create: a new microblading tool made of non-porous material, combining a smooth ergonomic design with an easy-to-attach pre-angled needle system.

Prototyping & validation?

We have gone through many rounds of prototypes to select the best needle type, angle configuration, stylus shape, material—down to each component you see today. There were a lot of iterations involved in the process of making a product that checks all our boxes. We are fortunate to have a group of amazing artists who tested the prototypes for us and provided their suggestions. Then our R&D team reviewed all the suggestions and made modifications to address any issues. From there, we test the final version of the working prototype, both internally and externally, before starting the production stage.

What’s next for the MEI-CHA R&D team?

Product development is a journey of discovery. This process of idea to reality involves lots of trial and error, and constant improvement of the product(s). As the Director of Product, I have enjoyed the challenges of problem-solving, and nothing is more rewarding than seeing concepts come to life.

We are working on ways to provide the artist more freedom and flexibility when it comes to machine permanent makeup. This is a project we are very excited about and will be sharing more details soon.

\\

Stay tuned for part two next month! What is your favorite MIDAS product? Tell us in the comments!

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.